"Step-by-Step Guide to Kitting and Assembly Services in Engineering "

Kitting and assembly services play a crucial role in the realm of Mechanical Engineering and Supporting Industries. Based on my extensive experience, I have witnessed firsthand the challenges and invaluable lessons learned from implementing these services in various projects. Understanding the intricate dynamics of kitting and assembly can significantly enhance efficiency and reduce costs, but it requires a careful approach. In this blog, I will share practical insights and hard-earned lessons from the field that can guide you in optimizing your kitting and assembly processes.

See Article Details At: kitting and assembly services

See Article Details At: kitting and assembly services

Common Mistake: Neglecting Proper Planning

One of the most significant mistakes observed in kitting and assembly services is inadequate planning. Many companies rush into the assembly phase without thoroughly analyzing the components and their requirements. This often leads to delays and increased costs. It is imperative to allocate sufficient time for planning, which includes:

View At: Kitting and Assembly Services for Efficient Production

- Identifying Required Components: Ensure all necessary parts are included in the kit.

- Creating a Detailed Assembly Plan: Outline each step of the assembly process.

- Establishing Clear Timelines: Set realistic deadlines to avoid last-minute rushes.

Overlooking Quality Control Procedures

Another critical oversight is the neglect of quality control procedures in kitting and assembly. Without a robust quality assurance process, the risk of assembling defective products increases significantly. Effective quality control should involve:

See More At: Step-by-Step Guide to Kitting and Assembly Services in Mechanical Engineering

- Regular Inspections: Conduct checks at various stages of assembly to catch errors early.

- Standardized Testing Protocols: Implement consistent testing methods for all assembled products.

- Feedback Mechanisms: Encourage team members to provide feedback on the assembly process for continuous improvement.

Ignoring Employee Training

Investing in employee training is often overlooked. Skilled assembly personnel are essential for the success of kitting services. Inadequately trained workers can lead to complications that impact productivity and quality. To address this issue, consider the following:

Reference: Real Lessons from Kitting and Assembly Services in Engineering

- Comprehensive Training Programs: Develop training sessions focusing on assembly techniques and safety protocols.

- Cross-Training Employees: Equip team members with various skills to enhance flexibility and efficiency.

- Continuous Learning Opportunities: Encourage employees to stay updated on industry trends and innovations.

Failing to Leverage Technology

In the rapidly evolving landscape of Mechanical Engineering, failing to leverage technology can be detrimental. Many businesses still rely on outdated methods, which can lead to inefficiencies. Embracing new technologies can significantly enhance kitting and assembly services. Key areas to focus on include:

- Automated Assembly Tools: Invest in automation to improve speed and precision in assembly processes.

- Inventory Management Software: Utilize software to track components and manage inventory effectively.

- Data Analytics: Implement analytics to assess performance and identify areas for improvement.

Neglecting Communication

Effective communication is often the backbone of successful kitting and assembly services. Poor communication can lead to misunderstandings, errors, and delays. To foster better communication, consider implementing the following:

- Regular Team Meetings: Hold frequent discussions to ensure everyone is on the same page.

- Clear Documentation: Maintain detailed records of assembly procedures, changes, and issues.

- Encouraging Open Dialogue: Create an environment where team members feel comfortable sharing concerns and suggestions.

Conclusion

In conclusion, the journey through kitting and assembly services in the Mechanical Engineering and Supporting Industries is fraught with challenges. However, by learning from past mistakes and implementing best practices, you can optimize your processes and drive success. Prioritizing planning, quality control, employee training, technology, and communication will equip your team to handle the complexities of kitting and assembly. Take these lessons to heart, and don't hesitate to seek professional guidance if needed. Start refining your kitting and assembly services today for a more efficient and productive future.

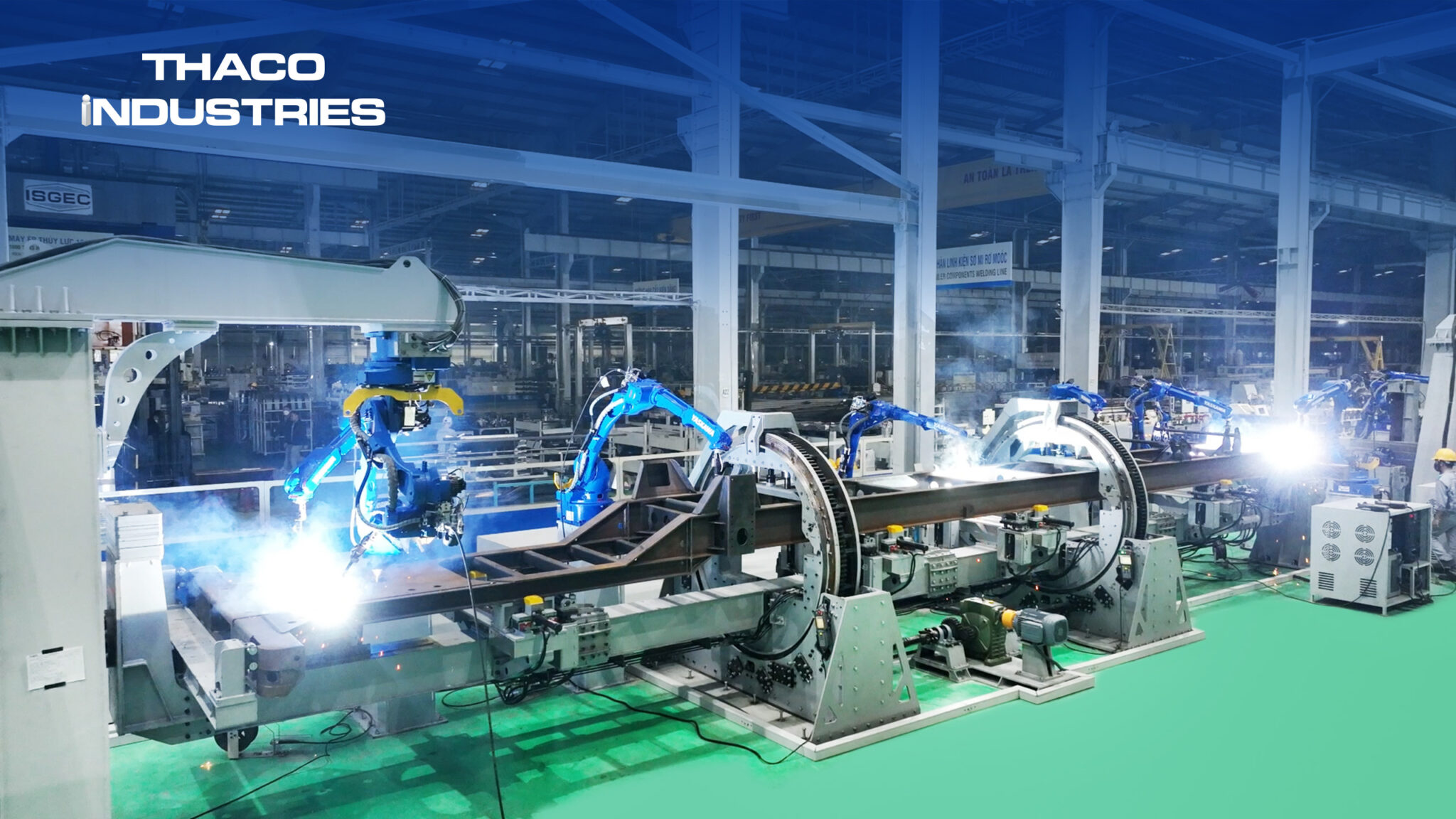

THACO Industries empowers global partners to scale production efficiently in Vietnam. Partner with THACO Industries for a comprehensive OEM manufacturing service in Vietnam, providing full-cycle OEM manufacturing that includes design engineering, fabrication, assembly, testing, and end-to-end logistics support.

#kitting_and_assembly_services, #kittingandassemblyservices, #THACO_Industries, #THACOIndustries, #THACO_Industries

Comments

Post a Comment