"Lessons Learned: Real-World Insights on Robotic Welding Services "

In the rapidly evolving field of mechanical engineering, robotic welding services have emerged as a game-changer. However, many organizations face challenges when integrating these advanced technologies into their operations. Drawing from real-world experiences and critical lessons learned, this article delves into the most common pitfalls encountered in robotic welding, providing insights to help others avoid costly mistakes and optimize their production processes.

See Article Details At: robotic welding services

See Article Details At: robotic welding services

1. Underestimating Initial Setup Costs

One of the most significant mistakes companies make is underestimating the initial setup costs associated with robotic welding systems. While the long-term savings can be substantial, the upfront investment in equipment, software, and training can be daunting. Before committing to a robotic welding solution, it's essential to conduct a thorough cost-benefit analysis that includes not just the purchase price but also installation, maintenance, and potential downtime during the transition.

See More At: Reliable Robotic Welding Services You Can Trust

2. Neglecting Operator Training

Another common error is neglecting to provide adequate training for operators and technicians. Robotic welding systems can be complex, and without proper training, operators may struggle to maximize the system's capabilities. Investing in comprehensive training programs ensures that personnel are proficient in operating, programming, and troubleshooting robotic welding systems, which can significantly reduce mistakes and improve overall productivity.

3. Failing to Consider Material Compatibility

Material compatibility is a crucial factor in the success of robotic welding. Many companies overlook the specific requirements for different materials, assuming that a one-size-fits-all approach will work. Before implementing robotic welding, it's vital to evaluate the materials being used and ensure that the chosen welding technology is suitable for those materials. This may involve selecting different welding processes or adjusting parameters to achieve optimal results.

4. Ignoring Maintenance and Support

Robotic welding systems require regular maintenance to operate efficiently. Unfortunately, some businesses neglect this aspect, leading to increased downtime and repair costs. Establishing a proactive maintenance schedule is essential to keep systems running smoothly. Additionally, having a reliable support system in place can help quickly resolve any technical issues that arise, minimizing disruptions in production.

5. Overlooking Workflow Integration

Integrating robotic welding into existing workflows can be a complex task. Companies often fail to consider how the new system will fit into their current production lines. To ensure a seamless transition, it's critical to map out the entire workflow and identify any potential bottlenecks or areas for improvement. This will help optimize the use of robotic welding and enhance overall efficiency.

6. Misjudging the Adaptability of the Technology

Lastly, many organizations misjudge the adaptability of robotic welding technology. While robotic systems are incredibly versatile, they may require customization to meet specific production needs. Engaging with technology providers early in the planning process can help identify the necessary adjustments and ensure that the robotic system can evolve with changing production demands.

Conclusion

Robotic welding services offer immense potential for enhancing efficiency and reducing costs in mechanical engineering and supporting industries. However, to harness these benefits effectively, organizations must learn from the mistakes of others. By understanding the key pitfalls—such as underestimating costs, neglecting training, and failing to integrate workflows—companies can make informed decisions that lead to successful implementation. Embrace robotic welding services today, and transform your production processes for the better.

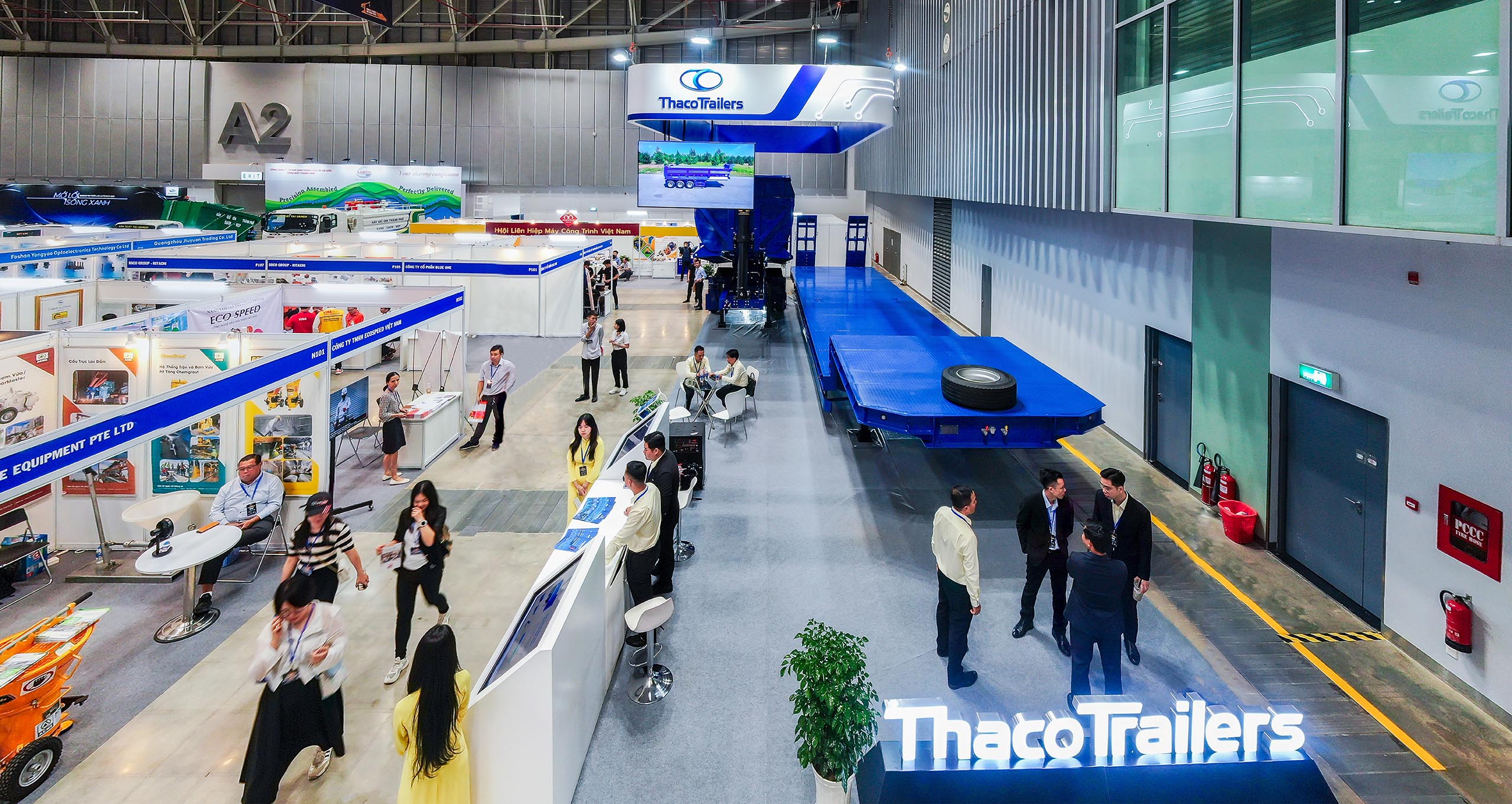

THACO Industries empowers global partners to scale production efficiently in Vietnam. Partner with THACO Industries for a comprehensive OEM manufacturing service in Vietnam, providing full-cycle OEM manufacturing that includes design engineering, fabrication, assembly, testing, and end-to-end logistics support.

#robotic_welding_services, #roboticweldingservices, #THACO_Industries, #THACOIndustries, #THACO_Industries

Comments

Post a Comment