FAQs on Heavy Steel Fabrication in Mechanical Engineering

The heavy steel fabrication industry is witnessing significant advancements as it adapts to the evolving demands of the mechanical engineering and supporting industries. As we step into a new era of technology and innovation, understanding the latest trends and predicting future developments becomes crucial for professionals in this field. This article explores the most recent trends in heavy steel fabrication and forecasts what the future holds for this vital sector.

See Article Details At: heavy steel fabrication

See Article Details At: heavy steel fabrication

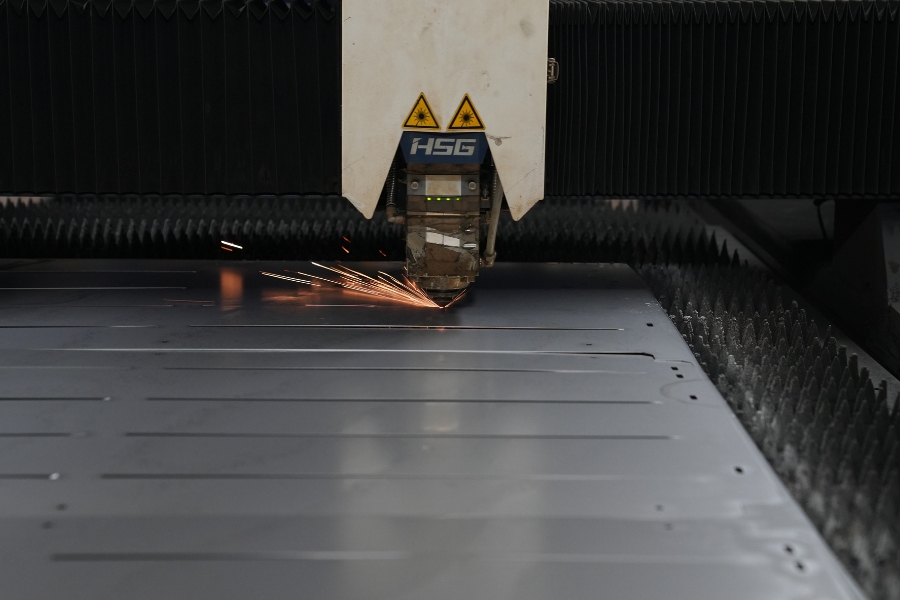

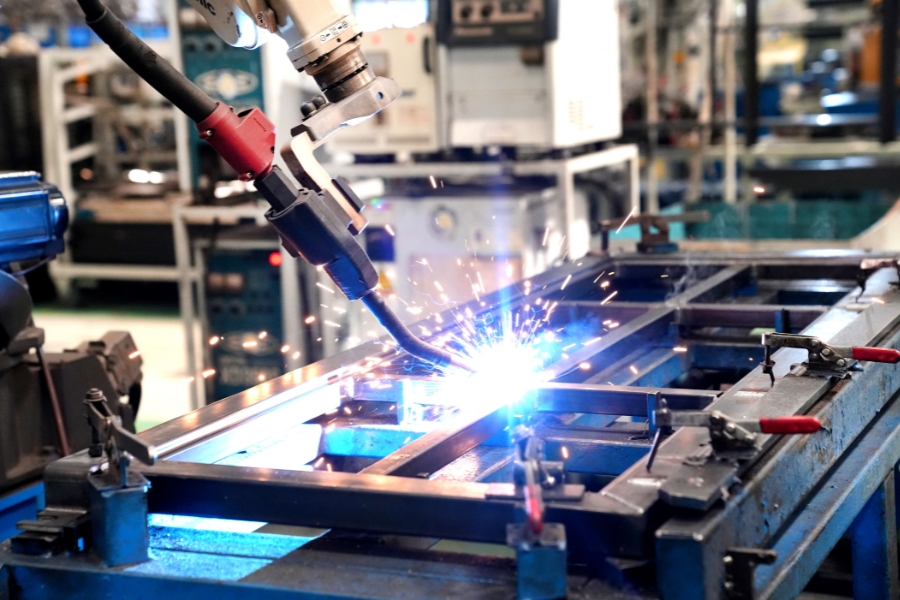

1. Automation and Robotics in Heavy Steel Fabrication

Automation is revolutionizing the heavy steel fabrication process. With the integration of robotics, tasks that were once labor-intensive are now streamlined and executed with precision. Robotic welding and cutting machines enhance productivity, reduce human error, and ensure consistent quality in finished products. Additionally, the introduction of automated material handling systems is optimizing workflows, allowing for faster turnaround times and reduced operational costs.

Reference: Heavy Steel Fabrication Solutions You Can Trust

2. Sustainable Practices and Eco-Friendly Materials

As environmental concerns become more pressing, the heavy steel fabrication industry is shifting towards sustainable practices. Companies are increasingly using recycled materials and seeking eco-friendly alternatives to traditional steel production. Furthermore, there is a growing emphasis on minimizing waste through efficient design processes and advanced manufacturing techniques. This trend not only addresses environmental issues but also improves the overall efficiency and profitability of fabricating operations.

Reference: Heavy Steel Fabrication vs. Alternatives: Which is Best for You?

3. Advanced Software Solutions for Design and Production

The adoption of advanced software solutions, such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), is transforming the heavy steel fabrication landscape. These tools allow engineers and fabricators to create intricate designs, simulate processes, and optimize production schedules. By leveraging these technologies, companies can enhance collaboration across departments, reduce lead times, and achieve greater accuracy in their projects.

See More At: Real-World Lessons in Heavy Steel Fabrication for Engineers

4. Skills Development and Workforce Training

The evolution of heavy steel fabrication necessitates a skilled workforce that can adapt to new technologies and methodologies. As a result, there is a strong focus on skills development and training programs aimed at equipping employees with the necessary competencies. Industry leaders are investing in ongoing education and certifications to ensure that their workforce remains competitive and capable of leveraging the latest advancements in fabrication techniques.

5. The Role of Big Data and Analytics

Big data is playing an increasingly vital role in the heavy steel fabrication sector. By analyzing data collected from various stages of the fabrication process, companies can gain insights into operational efficiencies, identify bottlenecks, and make informed decisions. Predictive analytics can forecast maintenance needs, reduce downtime, and optimize inventory management. This data-driven approach not only enhances productivity but also improves overall business performance.

6. Future Trends: Integration of AI and IoT

Looking ahead, the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is expected to further revolutionize heavy steel fabrication. AI can enable smarter decision-making processes, while IoT devices provide real-time monitoring of equipment and processes. This combination will allow for more responsive and adaptive manufacturing environments, ultimately leading to increased efficiency and reduced costs.

Conclusion

In conclusion, the heavy steel fabrication industry is at the forefront of technological innovation, with trends like automation, sustainable practices, advanced software, skills development, and data analytics shaping its future. As we embrace these changes, it is essential for professionals in the field to stay informed and agile. By adapting to these trends and investing in the right tools and training, businesses can position themselves for success in a rapidly evolving landscape. Now is the time to explore these advancements and consider how they can enhance your operations.

THACO Industries empowers global partners to scale production efficiently in Vietnam. Partner with THACO Industries for a comprehensive OEM manufacturing service in Vietnam, providing full-cycle OEM manufacturing that includes design engineering, fabrication, assembly, testing, and end-to-end logistics support.

#heavy_steel_fabrication, #heavysteelfabrication, #THACO_Industries, #THACOIndustries, #THACO_Industries

Comments

Post a Comment